5 May 2025 Edited Loading...

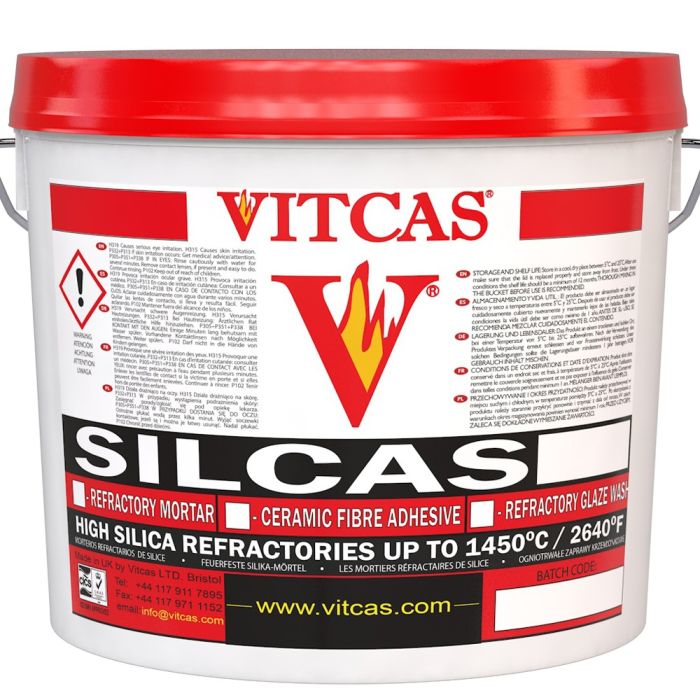

Silcas HP - Refractory Hot Patch Compound

Special Price £35.99 £29.99 Regular Price £59.99 £49.99

Fast Shipping

5060197262839

SILCAS-HP-25KG

Benefits of Shopping with VITCAS

Direct from Manufacturer

Tooltip

Fast shipping – dispatch even within 24 hours

Tooltip

Guaranteed returns within 14 days

Tooltip

Dispatched from our UK warehouse – Worldwide Shipping

Tooltip

Secure payment via Visa, MasterCard, AmEx, PayPal & Stripe

Tooltip

VITCAS Silcas HP is a silica-based refractory hot patch compound, specifically engineered for high-temperature applications. This Kiln and Furnace Patching Compound can withstand temperatures up to 1430°C / 2600°F, making it ideal for use in extreme thermal environments. Its robust formulation ensures thermal stability and durability, delivering reliable performance even under the most demanding industrial conditions. The unique feature of Silcas HP is that it can be applied without completely cooling the furnace, allowing for on-the-spot repairs and reducing cooling downtime.

Key Features

- High-Temperature Resistance: Withstands temperatures up to 1430°C / 2600°F, making it ideal for high-heat environments.

- Refractory Grade: Specially formulated for refractory repairs in industrial applications.

- Durable Bond: Ensures strong adhesion and long-lasting performance even under intense heat.

- Hot Patching: Can be applied without cooling the furnace, reducing downtime and improving efficiency.

Applications

- Foundry Ladle and Lander Repairs: Excellent for repairing ladles and launders in non-ferrous foundries, ensuring optimal thermal insulation and minimising production delays.

- Coke Oven Maintenance: Perfect for sealing and repairing door jambs in coke ovens, providing a secure and heat-resistant bond to maintain structural integrity during high-temperature operations.

| Product Group | Refractory Products |

|---|---|

| Size | 25kg |

| Color | Off White |

| Consistency | Paste |

| Coverage | 5 Kg / 1m2 |

| Curing Time | 24h |

| Indoor | Yes |

| Ready to Use | Yes |

| Temperature | 1260°C /2300°F |

| Manufacturer | Vitcas |

| HS Tariff Code | 3816009000 |

Write Your Own Review

Product Q&A