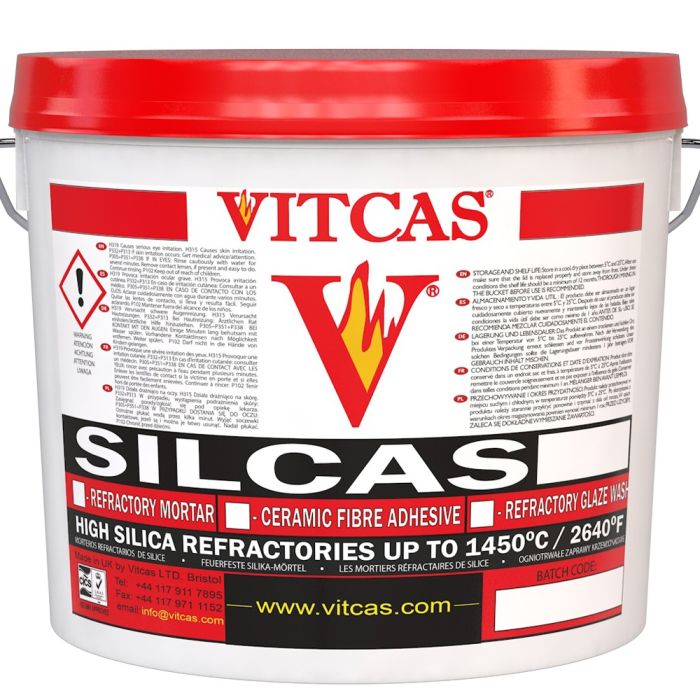

Silcas RGW- Refractory Glaze Wash Coating

Benefits of Shopping with VITCAS

Direct from Manufacturer

Fast shipping – dispatch even within 24 hours

Guaranteed returns within 14 days

Dispatched from our UK warehouse – Worldwide Shipping

Secure payment via Visa, MasterCard, AmEx, PayPal & Stripe

Silcas RGW - High Silica-Based Refractory Glaze Wash Coating

Vitcas Silcas RGW is a high silica-based refractory glaze wash coating engineered for industrial use in high-temperature environments. Formulated to perform at service temperatures up to 1000°C (1830°F), it provides enhanced protection and extended service life for refractory materials exposed to thermal cycling, abrasion, and chemical attack.

This advanced coating is thixotropic, meaning it maintains a thick consistency when undisturbed but flows easily during application. This ensures strong adhesion and a uniform glaze when applied to refractory substrates. Upon first heating to operating temperature, the coating vitrifies, forming a dense and chemically stable surface layer that improves refractory durability.

Key Features

-

High Silica Formulation: Improves chemical and thermal resistance of refractory surfaces

-

Thermal Resistance: Effective in environments up to 1000°C (1830°F)

-

Thixotropic Rheology: Easy to apply by brush, spray, or trowel while maintaining excellent coverage

-

Enhanced Surface Protection: Forms a dense glazed layer that protects against gas penetration, abrasion, and slag attack

-

Versatile Application: Suitable for use on bricks, castables, and other monolithic linings

Applications

- Refractory Brick Linings: Protective glaze coating for fire bricks in industrial kilns and furnaces

- Monolithic Refractories: Applied to castable or gunned linings in furnaces, boilers, and high-temperature reactors

- Ceramic Kilns: Glazing of interior refractory walls to reduce gas permeability and extend service intervals

- Metallurgical Furnaces: Surface treatment for linings in ladles, rotary kilns, and other thermally intensive equipment

Application Guidelines

Surface Preparation: Ensure the surface is dry, clean, and free of loose debris before application. Mixing: Stir thoroughly to activate the thixotropic properties. Application Method: Apply using a brush, spray equipment, or trowel depending on surface complexity. Brush application is recommended for maximum bond strength. Curing: Heat the coated refractory lining to 1000°C during the first firing to initiate glaze formation and achieve full vitrification.

| Product Group | Refractory Products |

|---|---|

| Size | 5kg |

| Color | Off White |

| Consistency | Paste |

| Coverage | 5 Kg / 1m2 |

| Curing Time | 24h |

| Indoor | Yes |

| Ready to Use | Yes |

| Temperature | 1260°C /2300°F |

| Manufacturer | Vitcas |

| HS Tariff Code | 3816009000 |