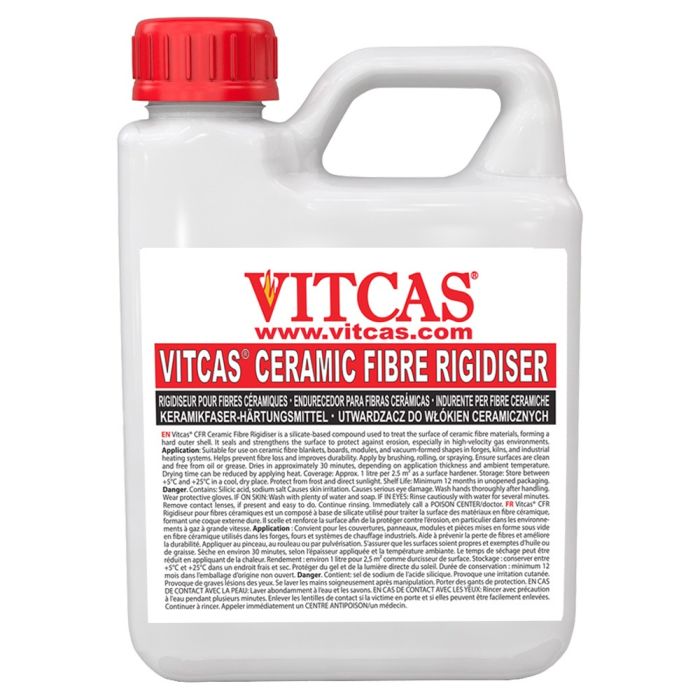

VITCAS Ceramic Fibre Rigidiser

Benefits of Shopping with VITCAS

Direct from Manufacturer

Fast shipping – dispatch even within 24 hours

Guaranteed returns within 14 days

Dispatched from our UK warehouse – Worldwide Shipping

Secure payment via Visa, MasterCard, AmEx, PayPal & Stripe

Vitcas® Ceramic Fibre Rigidiser is a silicate-based compound designed to treat ceramic fibre products such as blankets, modules, boards, and vacuum-formed components. It forms a hard outer shell, offering surface protection and sealing against erosion, especially in high-velocity environments. Ceramic Fibre Rigidizer is temperature resistant up to 1000°C (1832°F)

Applications:

- Surface Coating: Protects ceramic fibre materials exposed to high-velocity gases.

- Hardening Coat: Reinforces ceramic fibres used in forges.

- Sealing Coat: Prevents fibre shedding in ceramic kilns, ensuring cleaner work environments.

- Surface Hardener: Enhances durability of vacuum-formed ceramic fibre shapes.

Installation:

- Can be applied by brushing, dipping, rolling, or spraying.

- Ensure the ceramic fibre surface is clean and free of grease and oil before application.

- The rigidiser penetrates the surface and dries within 30 minutes.

Alternative Product Recommendation:

For high-performance applications requiring extreme heat resistance, VITCAS Zircon Paint Refractory Coating is highly recommended. Withstanding temperatures up to 1750°C (3182°F), it is ideal for kilns, furnaces, and industrial heat processing. This coating offers superior protection against thermal shock, abrasion, and chemical attack, ensuring long-lasting durability in the most demanding conditions.

| Product Group | Refractory Products |

|---|---|

| Size | 1L |

| Consistency | Liquid |

| Coverage | 1 l / 2.5 m2 |

| Ready to Use | Yes |

| Manufacturer | Vitcas |

| HS Tariff Code | 6806100000 |