10 November 2022 Edited Loading...

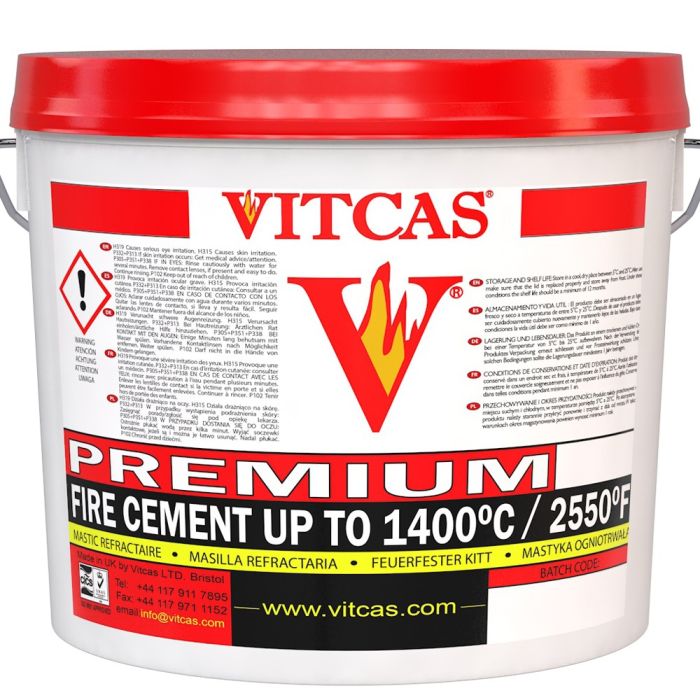

Premium 1P Sealing & Luting Compound 1400°C

Special Price £35.99 £29.99 Regular Price £59.99 £49.99

Fast Shipping

5060197262389

PREMIUM-1P

Benefits of Shopping with VITCAS

Direct from Manufacturer

Tooltip

Fast shipping – dispatch even within 24 hours

Tooltip

Guaranteed returns within 14 days

Tooltip

Dispatched from our UK warehouse – Worldwide Shipping

Tooltip

Secure payment via Visa, MasterCard, AmEx, PayPal & Stripe

Tooltip

Vitcas® Premium 1P Sealing and Luting Compound is a high-performance, heat-resistant compound engineered for the specific needs of white metal casting applications. It withstands temperatures up to 1400°C (2550°F) and provides an effective barrier to prevent the unwanted access of white metal to critical areas such as the base of bearings, header rings, oil channels, and dowel holes during both centrifugal and static casting processes. The compound is designed to offer excellent workability and high-performance protection in high-temperature environments.

Key Characteristics:

- Exceptional Adhesion: Bonds firmly to various surfaces, ensuring a secure seal during casting.

- Easy Application: The compound's consistency allows for smooth and precise application, making it easy to cover and protect specific areas from metal access.

- Machinable After Solidification: Once the white metal has solidified, the compound can be easily removed using standard machining techniques, simplifying post-casting processes.

- Non-Stick to Gloves: Designed for ease of handling, it will not adhere to protective gloves, improving safety and user comfort during application.

- Heat Hardening: The compound hardens and strengthens upon exposure to heat, ensuring lasting protection in the high-temperature casting environment.

- Protection Against White Metal Attack: Acts as a barrier to protect sensitive parts from direct contact with molten white metal, preventing erosion or damage.

Applications:

- Manufacturing & Relining of Bearings with White Metals: Used to create protective seals during the casting of white metals in bearings, ensuring precision and longevity in relined bearings.

- Centrifugal & Static Casting: Ideal for both dynamic and stationary casting methods where specific areas must be protected from white metal flow.

- Critical Component Protection: Shields key areas such as the base of bearings, header rings, oil passages, and dowel holes, preventing white metal from filling or damaging these regions.

| Product Group | Refractory Products |

|---|---|

| Size | 5kg |

| HS Tariff Code | 3816009000 |

Write Your Own Review

Product Q&A