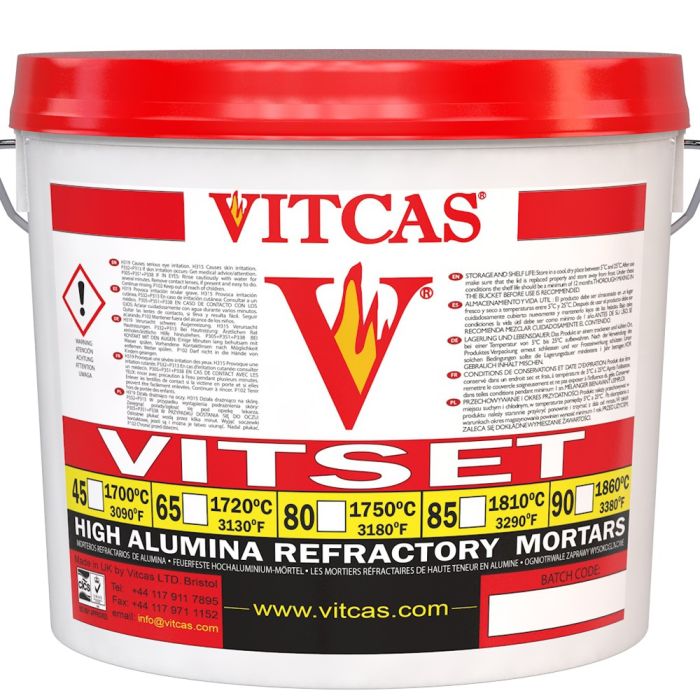

Vitset 45-Refractory Mortar Ready Mixed 1700°C

Benefits of Shopping with VITCAS

Direct from Manufacturer

Fast shipping – dispatch even within 24 hours

Guaranteed returns within 14 days

Dispatched from our UK warehouse – Worldwide Shipping

Secure payment via Visa, MasterCard, AmEx, PayPal & Stripe

Vitset 45 – Ready to Use Refractory Mortar up to 1700°C

VITCAS Vitset 45 is a specialised, ready-mixed, air-setting refractory mortar designed for high-performance applications in environments reaching up to 1700°C (3100°F). Engineered with a unique formulation, it offers an optimised consistency that is highly suitable for precision trowelling, patching, and setting various refractory materials. Vitset 45 distinguishes itself through its ability to form a durable, air-dried bond with a wide range of refractory products, including dense refractory bricks, lightweight insulating bricks and ceramic fiber components. This mortar exhibits superior adhesive properties, ensuring robust structural integrity in applications subjected to thermal cycling and aggressive environments exceeding 1400°C / 2600°F.

Key Features of High Alumina Refractory Mortar:

-

High-Temperature Resistance to 1700°C / 3100°F: Designed for extreme heat environments like metallurgy, cement, and ceramics, providing durable, long-lasting performance with minimal maintenance.

-

Ready-Mixed & Easy Application: Pre-mixed for quick use, offering a smooth consistency that allows for easy trowelling and setting without additional mixing, saving time and effort.

-

Air-Setting Bond Strength: Forms a strong, air-dried bond with dense refractory bricks, lighweight insulation bricks and ceramic fibre insulation, speeding up installation by eliminating the need for external heat.

-

Thermal Cycling Durability: Withstands rapid temperature changes without shrinkage and cracking, making it ideal for operations that experience frequent thermal cycling.

-

Chemical Resistance: Built to resist corrosive slag and chemical attacks, ensuring reliability in metallurgical and cement applications.

- Repair Efficiency: 5kg patches up to 20 fireproof bricks, setting within 24 hours at 20°C, ideal for fast repairs and installations.

Applications of Refractory Mortar:

- Foundry & Metallurgy: Furnace Linings: Ensures durable, heat-resistant seals for refractory bricks in foundry furnaces, withstanding extreme melting temperatures. Foundry Ladles: Provides strong bonds for ladle linings, resisting slag and thermal shock during molten metal handling. Blast Furnaces: Delivers heat-resistant lining for high-temperature environments in iron and steel production.

- Cement & Lime Industry: Rotary Kilns: Ideal for rotary kiln linings, resisting thermal cycling and mechanical wear for long-lasting performance. Preheater Towers: Forms strong bonds in preheater linings, preventing heat loss and maintaining efficiency.

- Kiln Linings & Ceramic Kilns: High Alumina ready-mixed refractory mortar provides excellent bonding for insulation bricks, enhancing thermal efficiency by minimising heat loss, while offering high-temperature resistance and stability during rapid temperature changes in ceramic kilns, kiln furnitures and kiln cars.

- Power Generation & Incineration: Boiler Linings: Provides thermal insulation and resistance in power plant boilers, suitable for fossil-fuel and waste-to-energy systems. Waste Incinerators: Resists high temperatures and corrosive byproducts in incinerators.

- Petrochemical Industry: Reforming Furnaces: Withstands high heat and corrosive gases in reforming furnaces. Gasifiers: Ensures durable linings in gasifiers for hydrocarbon-to-syngas conversion.

- Steel Industry: Tundishes: Resistant to slag and thermal cycling in continuous casting tundishes. Electric Arc & Induction Furnaces: Suitable for high-heat linings in steel melting furnaces.

- Marine & Ship Repair: Marine Incinerators: Resists high heat and corrosion in marine incinerators, reducing repair frequency. Ship Boilers: Provides durable lining and efficiency in marine boiler systems.

- Glass Manufacturing: Crown Linings & Regenerators: Secures refractory bricks in glass furnace crowns, resisting extreme heat and corrosion. Offers excellent stability against thermal shock and corrosion in glass melting process.

Instructions:

-

Surface preparation: Ensure that the surface to be repaired or lined is clean and free from dust, grease, and other contaminants. If necessary, use a wire brush or sandpaper to remove any loose material and ensure good adhesion.

-

Mixing: Vitset 45 is a ready-mixed refractory cement and does not require any additional mixing. However, it should be thoroughly stirred before use to ensure a consistent texture.

-

Application: Apply Vitset 45 using a trowel or spatula, pressing the material firmly into place. Ensure that the material is spread evenly and fills any gaps or cracks. Maximum 3 -5mm bed thickness.

-

Drying and curing: Allow the material to dry and cure for at least 24 hours at room temperature. Avoid exposing the material to moisture or high temperatures during this time.

-

Firing: After the material has cured, it can be fired gradually to the desired temperature. Follow the firing schedule recommended for your specific application.

Note that these are general instructions, and specific instructions may vary depending on the application and conditions.

| Product Group | Refractory Products |

|---|---|

| Color | Light Grey |

| Consistency | Trowelling |

| Coverage | 40 bricks (230x114x64mm) / 10kg |

| Indoor | Yes |

| Ready to Use | Yes |

| Temperature | 1700°C /3090°F |

| Drying Time | 24h / +20°C (+68°F) |

| Manufacturer | Vitcas |

| HS Tariff Code | 3816000000 |

-

Special Price £66.00 £55.00 Regular Price £96.00 £80.00Vitset 80-Refractory Mortar Ready Mixed 1750°C

Special Price £66.00 £55.00 Regular Price £96.00 £80.00Vitset 80-Refractory Mortar Ready Mixed 1750°C -

Special Price £78.00 £65.00 Regular Price £108.00 £90.00Vitset 85-Refractory Mortar Ready Mixed

Special Price £78.00 £65.00 Regular Price £108.00 £90.00Vitset 85-Refractory Mortar Ready Mixed -

Special Price £83.99 £69.99 Regular Price £118.80 £99.00Vitset 90 - VITCAS Refractory Mortar 1860°C

Special Price £83.99 £69.99 Regular Price £118.80 £99.00Vitset 90 - VITCAS Refractory Mortar 1860°C -

Special Price £56.39 £46.99 Regular Price £59.99 £49.99Refractory Castable Grade 1700°C

Special Price £56.39 £46.99 Regular Price £59.99 £49.99Refractory Castable Grade 1700°C