24 June 2024 Edited Loading...

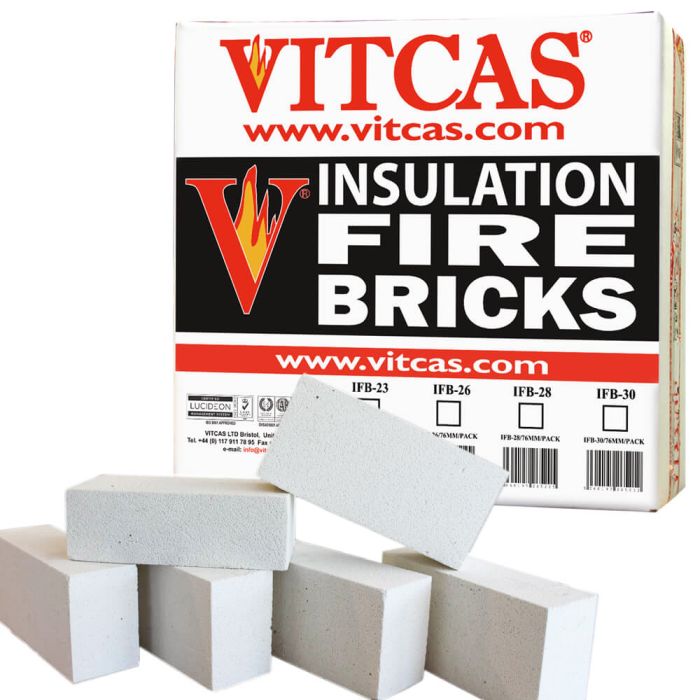

Insulating Fire Bricks-VITCAS Grade 26 -2600°F/ 1430°C

Special Price £3.35 £2.79 Regular Price £8.39 £6.99

Fast Shipping

5060197262273

IFB-26/76MM

Benefits of Shopping with VITCAS

Direct from Manufacturer

Tooltip

Fast shipping – dispatch even within 24 hours

Tooltip

Guaranteed returns within 14 days

Tooltip

Dispatched from our UK warehouse – Worldwide Shipping

Tooltip

Secure payment via Visa, MasterCard, AmEx, PayPal & Stripe

Tooltip

Vitcas Grade 26 Insulating Firebricks are expertly engineered through a controlled porosity process, delivering exceptional thermal, high temperature insulation with lightweight properties. The low thermal conductivity of Grade 26 insulating firebricks ensures faster heating and cooling cycles, making them ideal for furnace and energy-efficient kiln operations. For optimal installation, use Vitset 45 refractory mortar, specifically designed for high-temperature bonding. Size: 230x114x76mm Density: 800kg/m³

Key Features:

- Efficient Thermal Insulation: Refractory insulation and low thermal mass reduce energy consumption.

- Maximum Temperature: 1430°C (2600°F)

- Lightweight and Durable: Designed to handle repeated thermal cycling.

Applications for Primary Lining:

- Ceramic Kilns: Ideal for pottery, tiles, and brick manufacturing.

- Forges: Suitable for metalworking and blacksmithing operations.

- Heat Treatment Furnaces: Efficient heat containment for annealing, tempering, and other thermal treatments.

Applications for Secondary Insulation Layer (behind refractory linings):

- Furnaces and Kilns: Enhanced heat retention for industrial processing.

- Treatment Vessels & Regenerators: Improves operational efficiency in chemical processing.

- Gas Producers & Soaking Pits: Thermal insulation in steel and glass manufacturing.

- Stress Relieving Furnaces: Reliable thermal management for post-weld heat treatment.

- Reactor Chambers: Protects external structures from high internal temperatures.

| Product Group | Fire Bricks |

|---|---|

| Size | 230 x 114 x 76mm |

| Color | White |

| Temperature | 1430°C /2600°F |

| Manufacturer | Vitcas |

| Insulation | Yes |

| HS Tariff Code | 6902209100 |

Write Your Own Review

Product Q&A

We found other products you might like!

-

As low as £66.00 £55.00 Regular Price £96.00 £80.00Ceramic Fibre Blanket 1260°C

As low as £66.00 £55.00 Regular Price £96.00 £80.00Ceramic Fibre Blanket 1260°C -

As low as £90.00 £75.00 Regular Price £130.80 £109.00Ceramic Fibre Blanket 1430°C

As low as £90.00 £75.00 Regular Price £130.80 £109.00Ceramic Fibre Blanket 1430°C -

As low as £66.00 £55.00 Regular Price £95.99 £79.99Ceramic Fibre Board 1260°C-VITCAS Insulating Board

As low as £66.00 £55.00 Regular Price £95.99 £79.99Ceramic Fibre Board 1260°C-VITCAS Insulating Board -

As low as £90.00 £75.00 Regular Price £115.19 £95.99Ceramic Fibre Board 1430°C-VITCAS Insulating Board

As low as £90.00 £75.00 Regular Price £115.19 £95.99Ceramic Fibre Board 1430°C-VITCAS Insulating Board