Insulation is an important aspect of any high heat appliance, whether it is in your home or in industrial settings. When an appliance is properly insulated, it has many additional benefits conferred on it, i.e. it reduces heat loss which thus saves on energy consumption and as a result, is more environmentally friendly and more economically efficient. In the long term, this increases the life span of such appliances as they require less frequent repairs.

Advantages of Thermal Insulation

In the example of a bread and pizza oven, properly insulating it using ceramic fibre blanket, pizza oven wire and outdoor oven cement, will create many advantages.

Firstly, it will vastly enhance the quality and taste of the baked goods. This is because less heat will be lost and hence a consistent temperature can be maintained, in order to avoid over- or under-cooking.

Secondly, improved heat retention will result in increased food safety. In a poorly insulated oven, heat will be lost and pockets of cold air may enter the oven space, causing the pizza, bread or other food item to be unevenly cooked. In the case of fish or meat, this is particularly an issue because when it is not properly cooked throughout, it can lead to food poisoning. Therefore in order to ensure food safety and hygiene, insulation plays an important role.

Lastly, sufficient insulation of an oven is crucial for the safety of the person cooking or baking, as well as any other people in its vicinity, such as children, family or guests. This is due to the fact that poor thermal insulation will create a hotter external surface, which can unduly burn someone if they proceed to touch it. Therefore, effective insulation will prevent against disproportionately hot and potentially dangerous exteriors.

How Insulation Works- Modes of Heat Transfer

To better understand how insulation works, it is vital to first understand the basics. Heat transfer occurs between articles at different temperatures which can take place by three methods; conduction, convection and radiation.

An example of conduction is found in a kettle boiling water- the heating element inside transfers the heat to the water, thus increasing its temperature. On the other hand, convection is demonstrated by a radiator heating up the air within a room. Lastly, radiation is when someone sat by a fireplace can directly feel the heat emanating from it.

Furthermore, Thermal Insulation is defined as the reduction of heat transfer between materials at different temperatures and this is achieved mainly by reducing heat conduction. Insulation is usually achieved by trapping the air e.g. in the fibres of ceramic fibre cloth or inside the pores/bubbles of insulation fire bricks.

Common examples of insulation in the household include insulating a wood fired bread and pizza oven using ceramic fibre blanket or insulating around a fireplace or stove using a vermiculite board or fireplace construction board.

Similarly, examples of insulation in industrial settings include glass fibre needled felt mat being utilised in the petrochemicals industry, for furnaces in foundries or in power plants.

How to determine which insulation material to use for a specific application?

Generally, materials which are considered useful as thermal insulators have a low thermal conductivity, a low density and a low thermal mass.

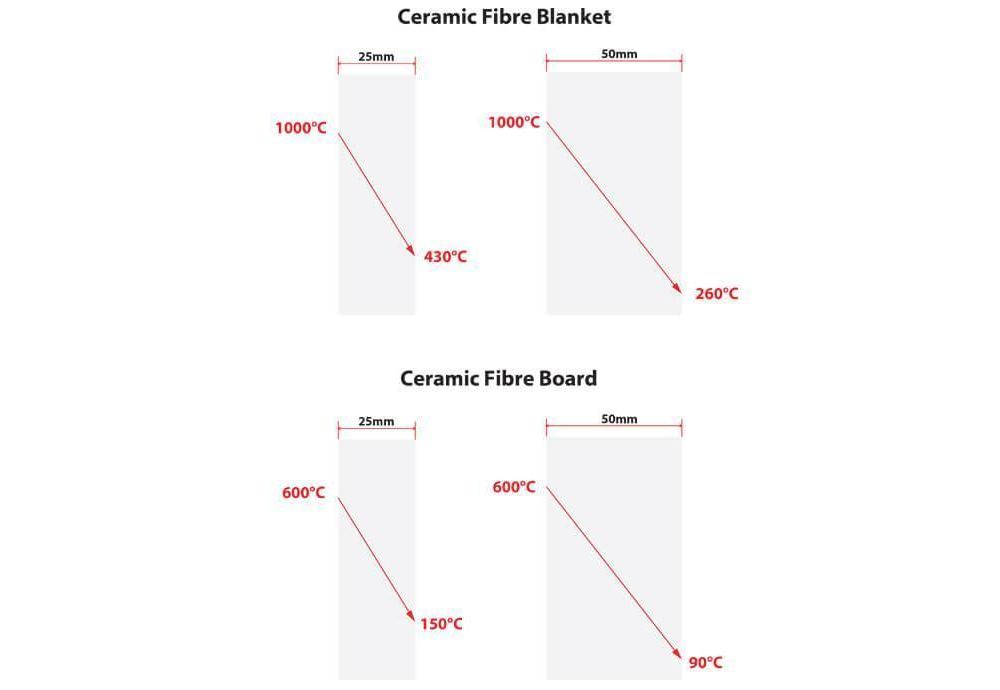

Obviously the main question that we want to answer in any situation is; “If the temperature of my object is x°C – which material and what thickness of insulation do I need to reduce the temperature on the outside to y°C?”

So the temperature reduction which can be achieved depends on the thermal conductivity of the insulation material and the thickness of the insulation material. A further consideration is that the thermal insulation must be able to withstand the temperatures which it will come into contact with. Polystyrene is a very effective insulation material at room temperature but if we need a material to function at 1,000°C for example then polystyrene will have melted and burned away.

Types of insulation materials- Temperature reduction as a result of their use

|

Insulation Material |

Thickness |

200°C |

500°C |

1000°C |

|

Vermiculite Board |

25mm |

80°C |

210°C |

450°C |

|

Construction Board |

30mm |

52°C |

90°C |

275°C |

|

Ceramic Fibre Blanket |

25mm |

56°C |

185°C |

425°C |

|

Ceramic Fibre Blanket |

50mm |

38°C |

112°C |

260°C |

|

HT Board |

12mm |

100°C |

235°C |

N/A |

|

Ceramic Fibre Paper |

5mm |

120°C |

340°C |

780°C |

|

Ceramic Fibre Cloth |

2mm |

180°C |

450°C |

900°C |

|

Insulation Fire Bricks Grade 23 |

114mm |

32°C |

62°C |

110°C |

From this we can easily see that high temperature cloths with thicknesses between 0.4mm and 2mm are not sufficient to use on their own but they do have a part to play in multilayered insulation applications.

For example, ceramic fibre blanket can be used in conjunction with aluminium cloth. Alternatively, insulation fire bricks can be used with a fireplace construction board.