31 May 2023 Edited Loading...

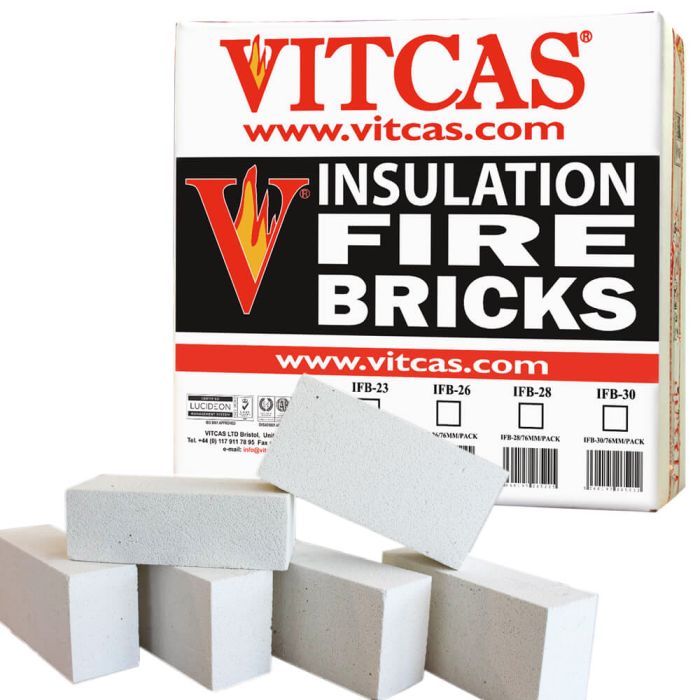

Insulating Fire Bricks-VITCAS Grade 23 - 2300°F/ 1260°C

Special Price £2.76 £2.30 Regular Price £7.19 £5.99

Fast Shipping

5060197262266

IFB-23/76MM

Benefits of Shopping with VITCAS

Direct from Manufacturer

Tooltip

Fast shipping – dispatch even within 24 hours

Tooltip

Guaranteed returns within 14 days

Tooltip

Dispatched from our UK warehouse – Worldwide Shipping

Tooltip

Secure payment via Visa, MasterCard, AmEx, PayPal & Stripe

Tooltip

Vitcas Insulation Fire Bricks are expertly crafted from high-purity refractory clays using an advanced manufacturing process that ensures a controlled pore structure. These bricks are significantly lighter in weight compared to traditional fireclay bricks, making them ideal for applications where heat storage is undesirable. With a remarkable resistance to temperatures up to 1260°C / 2300°F, Vitcas Grade 23 Insulation Fire Bricks offer superior thermal insulation and efficiency.

Key Features of Insulation Bricks

- High-Temperature Resistance: Withstand temperatures up to 1260°C / 2300°F.

- Lightweight Design: Easier to handle and install compared to fireclay bricks.

- Controlled Pore Structure: Enhances thermal insulation properties.

- Low thermal mass: The ability to rapidly absorb and release heat, resulting in shorter heating and cooling cycles in furnaces, thereby enhancing operational efficiency, increasing throughput, and reducing energy consumption. This makes the bricks particularly well-suited for industrial processes that demand frequent or rapid temperature fluctuations.

- Energy efficiency: Due to their superior insulating properties and low thermal mass, these bricks contribute to significant reductions in energy usage, optimising thermal management and lowering operational costs over time. This is especially critical for industries where energy consumption and thermal efficiency are key performance indicators.

- High Purity Materials: Made from premium refractory clays for exceptional durability.

- Dimensions: 230mm x 114mm x 76mm (9 x 4.5 x 3 inches)

Recommended Setting Material: Silcas M White Refractory Mortar 1260°C is recommended for optimal setting and performance of Grade 23 insulation bricks.

Applications

Primary Hot Face Refractory Lining:

- Ceramic Kilns: Ideal for providing thermal insulation in kilns used for firing ceramics, ensuring consistent temperatures and energy efficiency.

- Forges: Suitable for blacksmiths and metalworkers requiring high-temperature resistance and minimal heat retention.

- Heat Treatment Furnaces: Perfect for industrial applications involving the heat treatment of metals and materials, offering superior insulation and temperature stability.

Back-Up Insulation:

- Furnaces: Serve as back-up insulation behind other refractory materials, enhancing overall thermal performance.

- Kilns: Provide secondary insulation in various types of kilns, maintaining stable temperatures and reducing energy consumption.

- Flues: Ensure efficient insulation in flue systems, minimising heat loss and improving energy efficiency.

- Refining Vessels: Enhance thermal insulation in vessels used for refining processes, maintaining high temperatures and reducing heat loss.

- Heaters: Suitable for industrial heaters requiring high-temperature insulation and efficient heat management.

- Regenerators: Improve the thermal efficiency of regenerators by serving as secondary insulation.

- Gas Producers: Enhance the performance of gas production units by providing reliable insulation.

- Soaking Pits: Ideal for use in soaking pits, ensuring consistent heat retention and temperature control.

- Stress Relieving Furnaces: Provide effective insulation in furnaces used for stress relieving processes, ensuring uniform temperatures and efficient heat management.

- Reactor Chambers: Enhance the insulation of reactor chambers, ensuring optimal temperature stability and energy efficiency.

| Product Group | Fire Bricks |

|---|---|

| Size | 230 x 114 x 76mm |

| Color | White |

| Indoor | Yes |

| Temperature | 1260°C /2300°F |

| Manufacturer | Vitcas |

| Insulation | Yes |

| HS Tariff Code | 6902209100 |

Write Your Own Review

Product Q&A

Please provide your shipping details to determine available delivery options and to estimate the shipping costs for this product.

We found other products you might like!

-

As low as £66.00 £55.00 Regular Price £96.00 £80.00Ceramic Fibre Blanket 1260°C

As low as £66.00 £55.00 Regular Price £96.00 £80.00Ceramic Fibre Blanket 1260°C -

As low as £90.00 £75.00 Regular Price £130.80 £109.00Ceramic Fibre Blanket 1430°C

As low as £90.00 £75.00 Regular Price £130.80 £109.00Ceramic Fibre Blanket 1430°C -

As low as £66.00 £55.00 Regular Price £95.99 £79.99Ceramic Fibre Board 1260°C-VITCAS Insulating Board

As low as £66.00 £55.00 Regular Price £95.99 £79.99Ceramic Fibre Board 1260°C-VITCAS Insulating Board -

As low as £90.00 £75.00 Regular Price £115.19 £95.99Ceramic Fibre Board 1430°C-VITCAS Insulating Board

As low as £90.00 £75.00 Regular Price £115.19 £95.99Ceramic Fibre Board 1430°C-VITCAS Insulating Board