31 May 2023 Edited Loading...

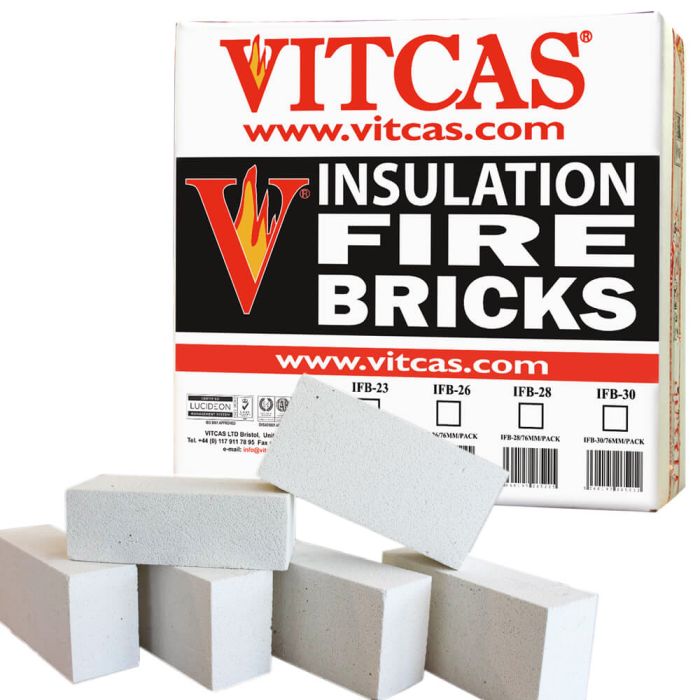

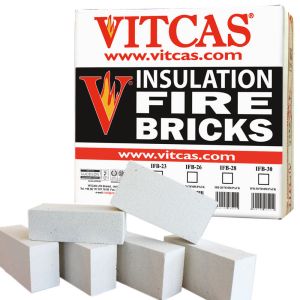

Insulating Fire Bricks-VITCAS Grade 28 -2800°F/ 1530°C

Special Price £4.56 £3.80 Regular Price £9.59 £7.99

Fast Shipping

5060197262280

IFB-28/76MM

Benefits of Shopping with VITCAS

Direct from Manufacturer

Tooltip

Fast shipping – dispatch even within 24 hours

Tooltip

Guaranteed returns within 14 days

Tooltip

Dispatched from our UK warehouse – Worldwide Shipping

Tooltip

Secure payment via Visa, MasterCard, AmEx, PayPal & Stripe

Tooltip

The insulation and exceptional refractory performance of VITCAS Insulating Fire Bricks - Grade 28, designed to withstand high temperatures up to 1530°C / 2800°F. Insulation fire bricks are manufactured to provide superior thermal insulation, making them indispensable in a variety of high-temperature industrial applications.

Key Features

- High-Temperature Resistance: Capable of withstanding temperatures up to 1530°C / 2800°F, ensuring reliable performance in extreme conditions.

- Porous, Lightweight Structure: Manufactured using a specialised method that results in a lightweight and porous structure, these bricks minimise energy waste by reducing heat absorption.

- Density: With a density of 900 kg/m³, these bricks offer excellent insulation properties while maintaining structural integrity.

- Low Iron Content: Ideal for applications where low iron content is crucial, such as in ceramic kilns.

- Dimensions: 230mm x 114mm x 76mm (9 x 4.5 x 3 inches)

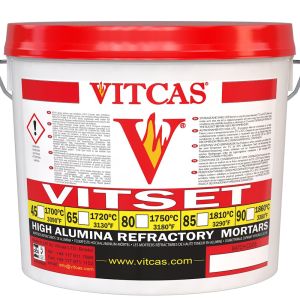

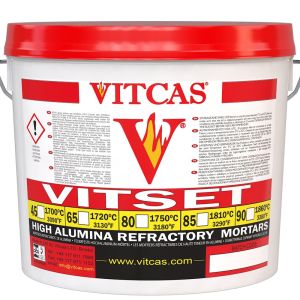

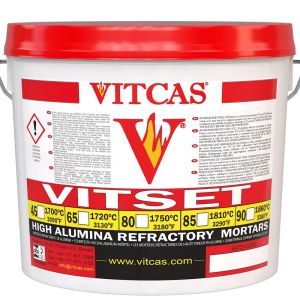

Recommended Setting Material: For best results, use Vitset 45 Refractory Mortar when setting Grade 28 insulation bricks.

Applications

Ceramic Kilns:

- Faster Turnaround: The lightweight nature of these bricks facilitates quicker heating and cooling cycles, enhancing productivity in ceramic kiln operations.

- Low Iron Content: Suitable for use in ceramic kilns due to their low iron content, which prevents contamination of the fired products.

Back-Up Insulation:

- Furnaces and Kilns: Serve as an additional insulation layer behind other refractory linings, boosting the overall thermal efficiency and stability of furnaces and kilns.

- Treatment Vessels: Enhance the insulation of treatment vessels, ensuring consistent temperatures and improved energy efficiency.

Glass and Enamel Furnaces:

- Non-Contact Areas: Perfect for use in areas of glass and enamel furnaces that are not in direct contact with molten products, providing reliable insulation and reducing heat loss.

| Product Group | Fire Bricks |

|---|---|

| Size | 230 x 114 x 76mm |

| Color | White |

| Indoor | Yes |

| Temperature | 1550°C /2820°F |

| Manufacturer | Vitcas |

| Insulation | Yes |

| HS Tariff Code | 6902209100 |

Write Your Own Review

Product Q&A

We found other products you might like!

-

Special Price £5.88 £4.90 Regular Price £11.94 £9.95Insulating Fire Bricks-VITCAS Grade 30 -3000°F/ 1650°C

Special Price £5.88 £4.90 Regular Price £11.94 £9.95Insulating Fire Bricks-VITCAS Grade 30 -3000°F/ 1650°C -

As low as £90.00 £75.00 Regular Price £130.80 £109.00Ceramic Fibre Blanket 1430°C

As low as £90.00 £75.00 Regular Price £130.80 £109.00Ceramic Fibre Blanket 1430°C -

As low as £90.00 £75.00 Regular Price £115.19 £95.99Ceramic Fibre Board 1430°C-VITCAS Insulating Board

As low as £90.00 £75.00 Regular Price £115.19 £95.99Ceramic Fibre Board 1430°C-VITCAS Insulating Board -

Special Price £47.99 £39.99 Regular Price £83.99 £69.99VITCAS Zircon Paint Coating 1750°C

Special Price £47.99 £39.99 Regular Price £83.99 £69.99VITCAS Zircon Paint Coating 1750°C