VITCAS Refractory Fire bricks 60% AL2O3

Benefits of Shopping with VITCAS

Direct from Manufacturer

Fast shipping – dispatch even within 24 hours

Guaranteed returns within 14 days

Dispatched from our UK warehouse – Worldwide Shipping

Secure payment via Visa, MasterCard, AmEx, PayPal & Stripe

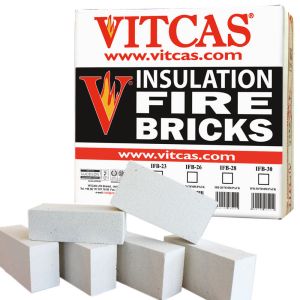

VITCAS Fire bricks 60% Alumina are Refractory Fire Bricks specially engineered to meet the most demanding high-temperature applications, rated as High Duty with a service temperature reaching up to 1600°C / 2910°F. 60% alumina (Al₂O₃) dense refractory bricks are essential for applications requiring high structural integrity and heat resistance in industrial processes that operate under extreme conditions. These dense bricks are well-suited for environments where they must endure extreme temperatures, mechanical stress, and chemical exposure. Each refractory brick, with dimensions of 230 x 114 x 64mm and weighing approximately 4.5 kg, is designed to offer exceptional performance and longevity.

Key Features of Refractory Bricks

- High Alumina Content: A minimum of 60% Al₂O₃ (aluminium oxide) for superior heat resistance and durability.

- High Temperature Resistance: Capable of withstanding extreme temperatures up to 1600°C / 2910°F, making them ideal for high-heat industrial applications.

- Low Iron Content: Reduces oxidation and enhances thermal stability under high temperatures.

- Low Alkali Content: Minimises degradation, prolonging the life of the bricks.

- Chemical Resistance: Excellent resistance to corrosive materials, such as molten metals, slag, and aggressive gases.

- Thermal Shock Resistance: Capable of withstanding rapid temperature changes, ideal for high-temperature fluctuations.

- Abrasion Resistance: Offers increased resistance to physical wear and tear.

- High Density and Strength: Ensures durability and a long lifespan under extreme conditions.

Applications

Dense refractory bricks 60% alumina - designed for high-performance industrial applications that demand exceptional heat resistance, durability, and mechanical strength.

-

Kiln Linings: These dense bricks are ideal for the primary linings of high-temperature kilns in industries such as ceramics, metallurgy, and cement. Their high alumina content ensures excellent durability, structural integrity, and resistance to thermal shock.

-

Ceramics Industry: Perfect for the construction and maintenance of furnaces used in the ceramics sector. The high alumina content provides superior resistance to wear and thermal cycling, ensuring long service life in kilns operating at extreme temperatures.

-

Metal Casting Furnaces: These bricks provide robust linings for metal casting furnaces, offering outstanding resistance to molten metals, slag, and chemical attack. Their mechanical strength and thermal resistance make them a reliable solution in continuous high-temperature metalworking operations.

-

Incinerators and Cremators: Specially engineered for use in incinerators and crematoriums, these bricks withstand prolonged exposure to high temperatures and aggressive waste byproducts. Their dense structure provides mechanical stability and extended service life in waste treatment and cremation systems.

-

Flue Gas Desulfurization Installations: In flue gas desulfurization systems, 60% alumina dense refractory bricks provide essential protection against the corrosive effects of sulfuric gases and chemicals, in addition to thermal insulation in high-temperature environments. These bricks help maintain the integrity of the flue system while optimizing the efficiency of gas cleaning processes.

-

Cement Kilns: With exceptional thermal and chemical resistance, 60% alumina bricks are ideal for lining cement kilns, where they resist the harsh effects of clinker reactions, high temperatures, and abrasion, ensuring consistent operation and reduced maintenance needs.

-

Petrochemical Plants: These dense bricks offer critical protection in high-temperature reactors and processing equipment in petrochemical plants. They provide outstanding resistance to chemical corrosion, erosion, and thermal shock, making them suitable for harsh environments with aggressive chemicals and high heat.

-

Blast Furnaces: Used for lining blast furnaces and hot blast stoves in steelmaking, these bricks provide excellent resistance to high temperatures, mechanical stress, and chemical exposure. Their high alumina content ensures optimal performance in demanding furnace environments.

-

Power Plant Boilers: In high-temperature regions of power plant boilers, these bricks offer exceptional resistance to thermal stress, erosion, and slag attack, ensuring the long-term reliability of boiler linings and contributing to improved thermal efficiency.

-

Glass Melting Furnaces: Although not in direct contact with molten glass, 60% alumina bricks are used in areas of glass furnaces where heat resistance and mechanical durability are required. Their stability at high temperatures helps maintain structural integrity and thermal efficiency.

Installation Recommendation

For optimal results, we recommend using VITCAS Refractory Mortar Vitset 45 for setting these 60% alumina bricks, ensuring a robust and durable installation. Alternatively, you may use higher grades of high alumina Refractory Mortars in the Vitset range - Vitset 80 or Vitset 90 resistant up to 1860°C / 3380°F.

Manufacturing Tolerance and Variations:

Please note that due to the inherent manufacturing process, there may be slight variations of +/-3mm in the size of the bricks. Similarly, subtle colour variations may occur between bricks, which does not affect the product's performance. It is also normal to find small chips on the bricks; this is not a product fault but rather a characteristic of the refractory fire brick. These can be easily covered by Refractory Mortar or Cement, if required.

| Product Group | Fire Bricks |

|---|---|

| Size | 230 x 114 x 64mm |

| Color | Buff |

| Outdoor | Yes |

| Indoor | Yes |

| Temperature | 1600°C /2910°F |

| Manufacturer | Vitcas |

| HS Tariff Code | 6902209900 |

-

Special Price £5.88 £4.90 Regular Price £11.94 £9.95Insulating Fire Bricks-VITCAS Grade 30 -3000°F/ 1650°C

Special Price £5.88 £4.90 Regular Price £11.94 £9.95Insulating Fire Bricks-VITCAS Grade 30 -3000°F/ 1650°C -

As low as £90.00 £75.00 Regular Price £130.80 £109.00Ceramic Fibre Blanket 1430°C

As low as £90.00 £75.00 Regular Price £130.80 £109.00Ceramic Fibre Blanket 1430°C -

As low as £90.00 £75.00 Regular Price £115.19 £95.99Ceramic Fibre Board 1430°C-VITCAS Insulating Board

As low as £90.00 £75.00 Regular Price £115.19 £95.99Ceramic Fibre Board 1430°C-VITCAS Insulating Board -

Special Price £47.99 £39.99 Regular Price £83.99 £69.99VITCAS Zircon Paint Coating 1750°C

Special Price £47.99 £39.99 Regular Price £83.99 £69.99VITCAS Zircon Paint Coating 1750°C