Energy is the hot topic this winter as global circumstances have led everyone to think about more efficient methods of creating a warm atmosphere in their home. However, have you ever considered the matrix range? This can be used in conjunction with your central heating to create warmth in any room in your home.

The Matrix Range

We delivered this article to discuss all the details you need to know about gas fire radiants, matrices, and artificial coals and logs in the matrix series.

Gas Fire Radiants

The first gas fires consisted of a simple row of burners with a radiant above each one. There are currently two widely used gas fires- radiant and convected gas fires. However, we will focus mainly on the former of these two.

Radiants are lightweight, ceramic elements which glow red in the flames of the burner. As the name suggests, this heats the objects in the room by the process of radiation. This is a very efficient method of heating one's property with a high heat output. So this upcoming winter, consider purchasing a gas fire instead of your regular electric fires or wood burning fireplaces.

The elements of a gas fire radiant need to be very porous and lightweight in order to ‘light up’ in the flames and unfortunately, this means that they are not very strong, quite brittle and easily broken.

The ceramic is based on a material called fused silica which has very low thermal expansion characteristics and consequently, high resistance to thermal shock. In manufacture, the ceramic composition is loaded with a burn out material such as sawdust, cork flakes etc so that when the articles are fired in the kiln this combustible material burns away and leaves the desired porous open structure.

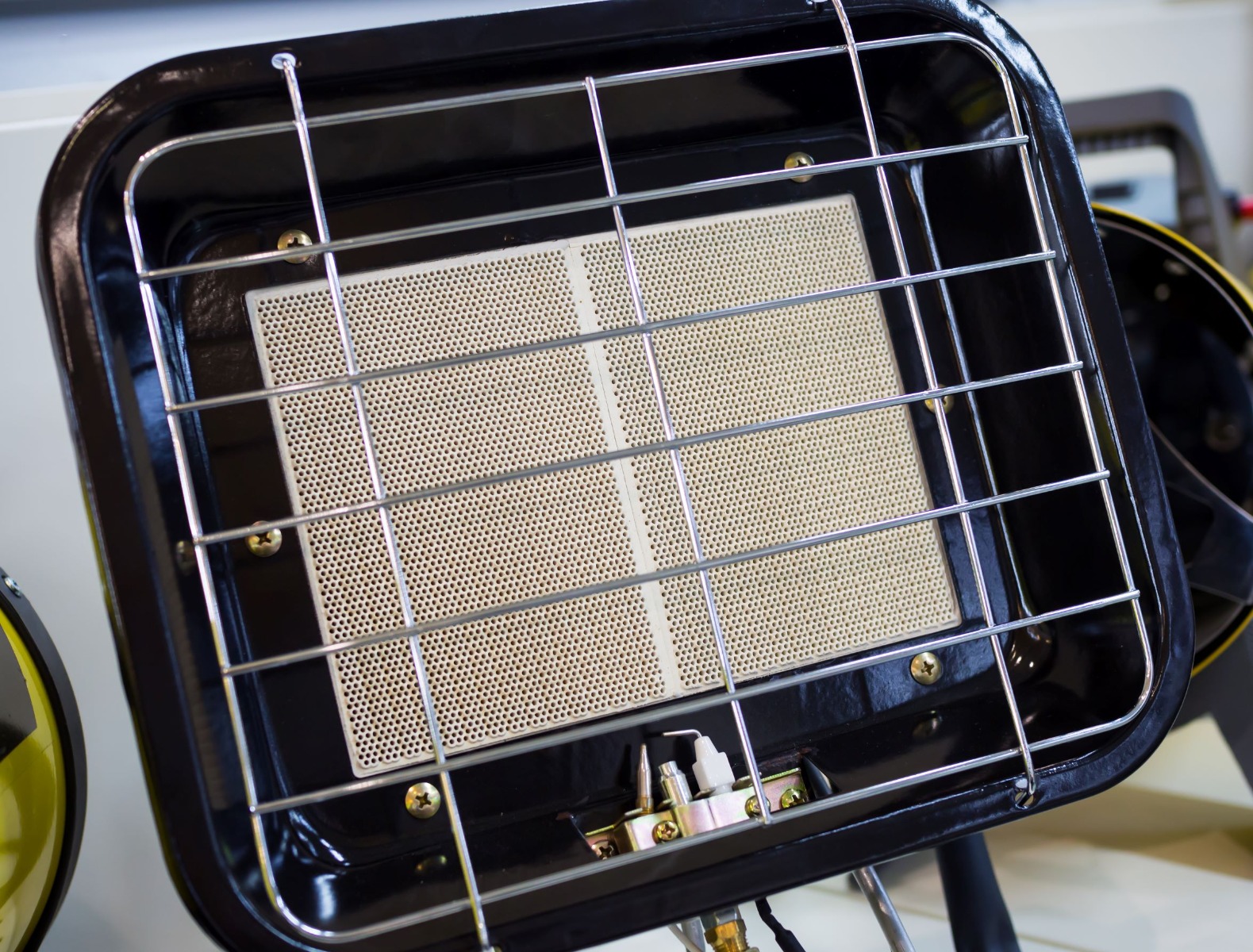

Matrices

More modern gas fires have a kind of tray support called a matrix with ceramic fibre coals or logs placed on top. When the gas is lit and the coals or logs are glowing red, the end impression is very similar to a real open fire. The matrix is manufactured from the same ceramic material as the radiants and therefore has the same characteristics of being lightweight, low strength and easily broken.

Artificial Coals and Logs

The coals and logs can be manufactured from ceramic fibre in a vacuum forming process or from the same ceramic material as the radiants and matrices.

They are then decorated with high temperature stains to make it look realistically like coals or logs. A better log is hand painted using several different colours for the most realistic appearance. You can usually opt for either black colour or a polished finish.

An additional element you can look to purchase if you do not have a traditional chimney system for gas fires is a balanced flue. This is more efficient as the balanced flue doesn't draw air from the room.

Repairing gas fire radiants and matrices

We offer a solution to repair your gas fire radiant. For this we recommend for you to use ourHeat Resistant Sealant.

Gas fire radiants and matrix elements are very lightweight, fragile and difficult to repair. If a repair is achieved then the material will not ‘light up’, that is, it will not glow red in the region of the repair because the material in that area will be denser.

Generally the item needs to be replaced but it is appreciated and we take note of the fact that sometimes replacements are not available.

Hence, these are our recommendations for attempting a repair without any guarantee that this can be achieved.

Maintenance of gas fires

It is very important that the coals / logs are correct for the appliance and are placed onto the matrix according to the pattern specified by the manufacturer of the gas fire. You should not place coals / logs randomly because it affects the gas burners. On a badly arranged fire there will be a build up of soot and carbon deposits under the coals / logs and also the danger of incomplete combustion of the gas which generates carbon monoxide.

The black colours tend to become more brown over time and they can be refreshed by spraying with Vitcas Heat Resistant Paint. If a radiant or matrix gets broken and a replacement is not readily available then a repair can be attempted with Vitcas Heat Resistant Sealant as follows:

- Put the parts to be reunited in a bowl or bucket under water and make sure they are thoroughly soaked. They will absorb a lot of water.

- Take a metal tray (or oven tray) and assemble the items using Vitcas Heat Resistant Sealant as the adhesive. Push the parts together and scrape away the excess which is squeezed out. Once assembled, do not disturb the items again.

- Pick up the tray and put into an oven (cooker) at about 100 degrees C for 3 – 4 hours.

- Take the tray out of the oven and leave to cool.

- If the repair has been successful the element can now be replaced in the appliance.

Bear in mind that the areas which have been repaired will not light up and glow like the rest of the part because the sealant has a higher density than the radiant material.

Following our steps should ensure that you repair your gas matrix correctly and that the whole process runs smoothly.