VITCAS Fire bricks 230x114x76mm

Benefits of Shopping with VITCAS

Direct from Manufacturer

Fast shipping – dispatch even within 24 hours

Guaranteed returns within 14 days

Dispatched from our UK warehouse – Worldwide Shipping

Secure payment via Visa, MasterCard, AmEx, PayPal & Stripe

Fire Bricks 42% Alumina - High Duty Refractory Bricks for Extreme Heat Applications

VITCAS 42% Alumina Fire Bricks are engineered for excellence, classified as High Duty bricks. These fire bricks are capable of withstanding extreme temperatures, with a maximum service temperature of up to 1430°C /2600°F. Each fire brick measures 230 x 114 x 76mm (9" x 4½" x 3") and weighs approximately 4.5 kilograms, meticulously designed for high-performance applications.

Key Features

-

Alumina Content: Contains a minimum of 42% Al₂O₃ (aluminium oxide), ensuring excellent refractoriness and heat resistance

-

Low Iron Content: Reduces oxidation risks and enhances thermal stability in reducing atmospheres

-

Low Alkali Content: Reduces the risk of alkali-related degradation, improving chemical durability and brick lifespan

-

Thermal Shock Resistance: Withstands rapid heating and cooling cycles without cracking-ideal for high-temperature, high-stress environments

-

Abrasion Resistance: Built to endure mechanical wear from fuels, tools, or product movement

-

High Density and Strength: Dense composition provides excellent load-bearing strength and thermal efficiency

Applications

- Kiln Linings: Perfect for use in high-temperature kilns in ceramics and metal casting industries.

- Ceramics: Ideal for the construction and maintenance of ceramic furnaces.

- Metal Casting: Provides reliable and efficient lining for metal casting furnaces.

- Incinerators and Cremators: Exceptionally suited for high-temperature incinerators and crematoriums.

Installation Recommendation

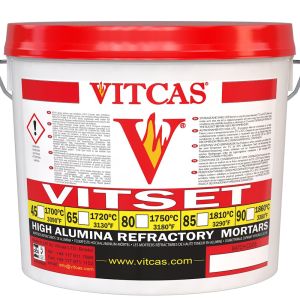

For the best results, we recommend using Vitset 45 - Refractory Mortar 1700°C for setting Vitcas 42% alumina fire bricks, ensuring a strong and durable bond.

Additional Support

Unsure about the quantity needed for your project? Use our Vitcas Quantity Calculator for guidance, ensuring you get the perfect amount for your specific requirements.

Manufacturing Tolerance and Variations:

Please note that due to the inherent manufacturing process, there may be slight variations of +/-3mm in the size of the bricks. Similarly, subtle colour variations may occur between bricks, which does not affect the product's performance. It is also normal to find small chips on the bricks; this is not a product fault but rather a characteristic of the fire clay brick. These can be easily covered by Refractory Mortar or Cement, if required.

| Product Group | Fire Bricks |

|---|---|

| Size | 230 x 114 x 76mm |

| Color | Buff |

| Outdoor | Yes |

| Indoor | Yes |

| Temperature | 1430°C /2600°F |

| Manufacturer | Vitcas |

| HS Tariff Code | 6902209100 |

-

Special Price £4.20 £3.50 Regular Price £6.00 £5.00VITCAS Refractory Fire bricks 60% AL2O3

Special Price £4.20 £3.50 Regular Price £6.00 £5.00VITCAS Refractory Fire bricks 60% AL2O3