In the late 18th century, the annals of maritime history were enriched by the advent of the steam-powered vessel, often referred to as the steamboat. The steam engine, an innovation of revolutionary significance, sat at the heart of these potent machines. It harnessed the power of steam as a working fluid to execute mechanical work. The adoption of steam power fundamentally reshaped the realm of maritime transport, setting a new course for vessels worldwide.

In this article, we aim to take you on a voyage through history to learn about the genesis of this wonderful invention.

Pioneers in Steam Power: The Early Steamboats

An account of steam-powered navigation would be incomplete without mentioning Robert Fulton, a key figure in this maritime evolution. Fulton commissioned a steamboat that navigated the Hudson River in the United States, marking a significant milestone in maritime history. The steamboat made use of a steam engines with a high-pressure cylinder to create steam, providing the propulsion required to power the vessel. This pioneering innovation influenced the design of countless subsequent steamboats, laying the foundation for a new era of steam navigation. By the 19th century, steamboats had become a common sight on the Hudson River and in New Orleans on the Mississippi River, signifying a new era dominated by steam power.

While Fulton often takes the credit for pioneering this form of transportation, it was, in fact, John Fitch, an American inventor, who built and set sail on the first successful steamboat. The first successful trial took place in 1787 on the Delaware River. However, after years of vying for federal protection in the form of a patent for his invention, he finally received it but, to his dismay, he was not the only one. James Rumsey also received a patent and the Patent Board rejected Fitch's claims to being the one to build and publicly set sail on the first voyage on a steam boat.

While this article aims to focus on the UK and Europe, it is noteworthy that the United States began using steam boats widely prior to the American Civil War and steamboat traffic rose significantly across the Mississippi River. Both commercial transportation of cargo and transport of passengers became popular during this time.

James Watt is another notable figure when it comes to this subject. A Scotsman, who was not the inventor, but he made significant steps in improving how steam engines operated, making them more efficient, cost effective and sustainable by reducing the amount of waste they produce.

Steamboat Engine Power and Bristol's Maritime Heritage

Bristol, nestled in the southwest of the United Kingdom, is steeped in a rich maritime history, in which the advent of steam power played a pivotal role. Located at the confluence of the River Avon and Frome, Bristol has been a hub for seafaring and maritime trade since the Middle Ages.

In the 19th century, at the zenith of the Industrial Revolution, Bristol emerged as a nexus for steam-powered vessels, significantly enhancing its role as a centre for commerce and industry. Bristol's docks teemed with activity, with steamboats regularly setting sail for various destinations in the UK and Europe.

A standout link between the city and steam-powered ships is the SS Great Britain, a ship born from the genius of the engineer Isambard Kingdom Brunel. Launched in 1843, this was the largest vessel of its time and the first iron steamer to cross the Atlantic, achieving this feat in 14 days. This imposing steamship embodies the technological advancements of the 1800's and Brunel's contribution to the evolution of steam-powered ships. Today, the SS Great Britain is preserved as a hull of a ship in a museum in Bristol Harbour, where it stands as a testament to the city's rich maritime heritage and the transformative power of steam navigation.

Canal Boats- Steam Engines

Moreover, Bristol played an instrumental role in the development of steam-powered canal boats, also referred to as barges. The Kennet and Avon Canal, connecting Bristol with Reading, emerged as a bustling conduit of commerce in the 19th century, with steam-powered narrowboats ferrying goods across the country.

The Steam-Powered Revolution in the United Kingdom and Europe

In parallel with developments in the United States, the United Kingdom and the rest of Europe wholeheartedly embraced the potential of steam power. British steamboats, like the steam tug that aided navigation on the Forth and Clyde Canal, played a key role in navigating narrow waterways. This heralded the start of an industrious era of steam-powered vessels across Europe, showcasing the adaptability and benefits of these machines.

Canal boats, in particular, became an integral part of the transportation system, boosting trade and transportation on inland waterways, not only in the United Kingdom but across the continent. The first example of this was the barge called the Charlotte Dundas, named after the daughter of Lord Dundas, who was the Governor of Forth & Clyde Canal Company. Dundas commissioned William Symington to design this barge at the beginning of the 1800s before the likes of Fulton did the same on a larger scale.

The Industrial Revolution and its Influence on Steamboat Design

The 19th century, defined by the industrial revolution, saw a surge in innovation in steamboat engine design. A notable shift took place in the propulsion methods employed by most steamboats - paddle wheels were gradually replaced by screw propellers. Initially tested on the steam-powered submarine, Resurgam, the screw propellers were praised for their superior performance in rough seas and soon became a staple in steamboat construction.

Alongside this, there was another critical advancement in steamboat engineering - progress in the boiler's construction. As the boiler's design evolved, it resulted in larger, more robust boilers capable of operating at significantly higher pressures—often measured in pounds per square inch (psi). This advancement led to a considerable increase in the efficiency of most steamboats' engines and extended the range of voyages without the need for recoaling, thereby broadening the operational capabilities of steam-powered boats.

In the 20th century, river navigation and canals were superseded by railroads.

The Role of the Steamboat in Transatlantic Travel

The advent of steam navigation exerted a profound impact on transatlantic travel. Before the introduction of steam power, journeys across the Atlantic Ocean were largely subject to the whims of wind and weather. However, the steam engine heralded a new era of reliability and speed, with steam navigation enabling more consistent and dependable routes for transporting cargo and passengers. This era of steam power remained dominant in the maritime transport landscape until the formidable advent of the internal combustion engine.

Contemporary Steamboats: Keeping the Tradition Alive

While the age of large steamships may have passed, the charm of smaller steamboats persists. Enthusiasts worldwide continue to restore and construct new steam boats, harmoniously blending traditional and modern methods to recreate these historical crafts. This particular niche within maritime engineering remains vibrant, carrying the legacy of steam power into the modern age.

In the European Union, the construction of small boats is governed by the Recreational Craft Directive, implemented in 1998. This directive mandates the use of non-combustible materials within the engine space, ensuring safety standards are upheld within the steamboat construction landscape.

Model Steamboat Building: A Testament to Craftsmanship

The influence of steam power extends beyond full-sized vessels, reaching into the intricacies of model building. Crafting model steam boats has emerged as a popular hobby among maritime enthusiasts. Even though insulation presents less of a concern at this smaller scale, creating these miniature models demands precision and meticulous attention to detail. Boilers are often clad with wooden lagging strips and elegantly secured in place by brass bands, giving these creations an authentic and appealing finish.

Refractory Materials: The Unsung Heroes of Steam Power

The use of steam power on maritime vessels necessitated the application of refractory materials - substances that retain their strength at high temperatures. In steam boats, these materials were used primarily in the construction of the boiler and firebox, serving as a crucial barrier against the extreme heat generated by burning a fuel of coal or wood.

Refractory materials needed to meet rigorous criteria: they were required to withstand high temperatures, resist thermal shock, and remain chemically stable. Early steamboats frequently employed firebrick as a refractory material, which, despite its susceptibility to thermal shock, was appreciated for its high melting point and ability to withstand wear and corrosion.

However, as steamboat technology progressed, so did the materials used. By the mid-19th century, more advanced refractories like silica and high alumina bricks began to be used, offering better resistance to thermal shock and higher melting points. These newer materials significantly improved the longevity and safety of steamboat boiler stoves.

High-Temperature Insulation Materials: An Essential in Steam Power

High-temperature insulation materials, indispensable for maintaining efficiency and safety on a steamboat, also warrant recognition. Given the intense heat generated within a steam engine, effective insulation was essential to prevent excessive heat loss, protect other components and machinery from thermal damage, and ensure the safety of the crew, passengers and cargo.

In the early days of steam navigation, materials such as asbestos were commonly used for insulation due to their excellent heat resistance. However, over time, the significant health risks associated with asbestos led to its replacement with safer high-temperature insulation materials.

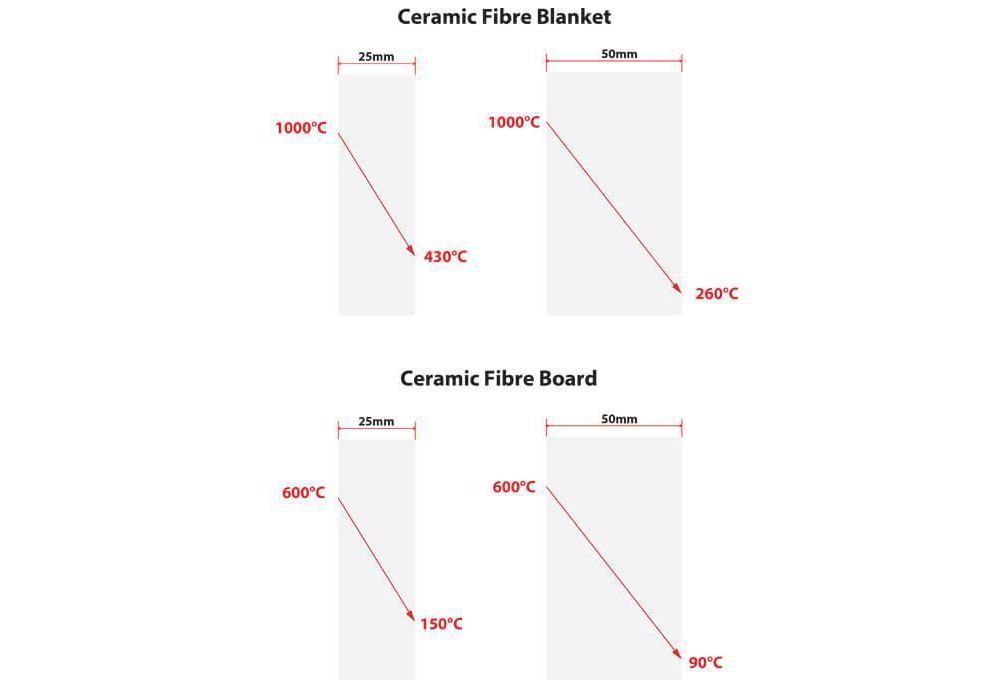

Modern insulation materials include calcium silicate, fibreglass, and various types of ceramic fibre, each offering distinct advantages. Calcium silicate, for example, can maintain its strength at extreme temperatures, making it an excellent choice for insulating high-temperature steam pipes. Fibreglass, on the other hand, combines excellent thermal resistance with being lightweight and easy to work with. Ceramic fibre insulation can withstand extremely high temperatures, making it an ideal insulation material for the most heat-intensive areas of a steamboat.

These materials have not only safeguarded steamboats from heat damage but also made them more efficient. By reducing heat loss, they ensure that more of the energy produced in the combustion process is harnessed to generate steam, maximising the steam engine's power output.

In essence, refractory and high-temperature insulation materials are unsung heroes in the narrative of steam-powered ships and vessels. Their development and use, often overlooked, have significantly contributed to the safety, efficiency, and longevity of these iconic vessels, further exemplifying the intriguing interplay of engineering, innovation, and resilience in maritime history.

For insulation materials specifically designed for boats and barges, visit our shop.

Conclusion

From the mighty Mississippi River to the expansive Atlantic Ocean, steam boats, propelled by the remarkable steam engine, have indelibly charted the course of our history. The transformative power of steam has redefined the maritime industry, leaving a legacy that remains visible even today. Whether it's the restoration of a historic steam tug, the crafting of a canal boat or the construction of a model steamboat, the spirit of these steam-powered marvels continues to inspire and captivate enthusiasts around the world.