2 June 2025 Edited Loading...

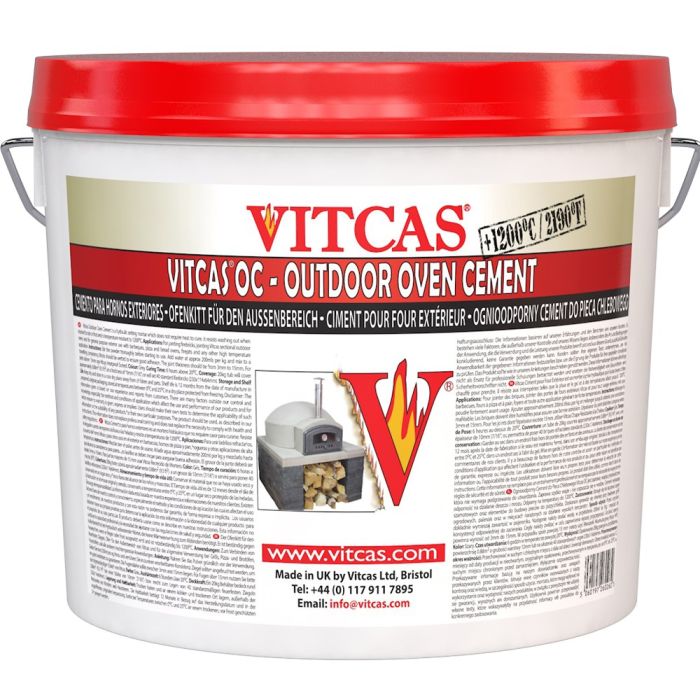

OC - Outdoor Oven Cement

Only %1 left

As low as £17.99 £14.99 Regular Price £23.99 £19.99

Fast Shipping

VITCAS-OC

Benefits of Shopping with VITCAS

Direct from Manufacturer

Tooltip

Fast shipping – dispatch even within 24 hours

Tooltip

Guaranteed returns within 14 days

Tooltip

Dispatched from our UK warehouse – Worldwide Shipping

Tooltip

Secure payment via Visa, MasterCard, AmEx, PayPal & Stripe

Tooltip

Please provide your shipping details to determine available delivery options and to estimate the shipping costs for this product.

Vitcas Outdoor Oven Cement - Pizza Oven Mortar

Vitcas Outdoor Oven Cement is a pre-mixed dry powder refractory mortar formulated for jointing fire bricks and assembling Vitcas Sectional Wood Fired Outdoor Pizza Ovens. It is ideal for exterior high-temperature applications requiring firebrick jointing, offering excellent performance in a wide range of outdoor heating projects. Resistant to 1200°C / 2190°F. Coverage: 10kg tub is suitable for jointing approximately 15 fire bricks (230x114x64mm) or around 0.44m² (4.75ft²) with a joint thickness of 10mm (7/16").

Key Characteristics

- Water-Resistant: Insoluble in water, ensuring long-lasting durability even when exposed to moisture.

- No Heat Cure Required: Sets naturally without the need for heat.

- Frost and Rain Resistant: Resists washing out when exposed to frost or rain, making it ideal for outdoor use.

Applications

- Barbecues: Ideal for securing firebricks and sealing joints in outdoor barbecue structures, ensuring long-lasting performance under high heat.

- Outdoor Pizza Ovens: Perfect for jointing the fire bricks in wood-fired outdoor pizza ovens, providing strong and heat-resistant joints that can withstand repeated exposure to extreme temperatures.

- Bread Ovens: Suitable for traditional bread ovens, where it ensures a durable seal that can handle the prolonged high temperatures required for baking.

- Smokehouses: Provides excellent sealing for smokehouse fire chambers, ensuring heat retention and smoke control for consistent cooking results.

- Fire Pits: Excellent for constructing and maintaining fire pits, offering a reliable bond that can endure direct exposure to flames and high temperatures.

- Outdoor Fireplaces: Suitable for building or repairing outdoor fireplaces, ensuring a strong and durable bond in areas subject to extreme heat.

- Garden Incinerators: Can be used in the construction or repair of garden incinerators, providing heat-resistant sealing for prolonged burning sessions.

- Tandoor Ovens: Perfect for sealing and maintaining traditional tandoor ovens, offering long-term durability under intense heat.

Instructions

- Preparation: Open the container and stir the dry product thoroughly before adding water.

- Mixing: Combine the dry powder with water to achieve a trowelling consistency. Use approximately 180ml of water per 1 kg of material.

- Brick Preparation: Wet the fire bricks before applying the oven cement to ensure optimal adhesion.

- Joint Thickness: Suitable for joint thicknesses starting from 3mm. For gap-filling over 15mm, use Vitcas Heatproof Screed.

- Setting Time: The oven cement will set within a few hours, with longer setting times in cold weather.

Note: We do not recommend the addition of cement dye or pigment for this product.

| Product Group | Mortars/ Cements |

|---|---|

| Color | Grey |

| Consistency | Powder |

| Coverage | 10kg - 15 bricks(230x114x64mm) / 0.44m2 (4.75ft2) at 10mm(7/16") |

| Outdoor | Yes |

| Temperature | 1200°C /2190°F |

| Drying Time | 24h / +20°C (+68°F) |

| Manufacturer | Vitcas |

| Mix with water | Yes |

| HS Tariff Code | 3816000000 |

Write Your Own Review

Product Q&A

We found other products you might like!

-

As low as £3.00 £2.50 Regular Price £4.80 £4.00Vitcas-Fire Bricks-Yellow

As low as £3.00 £2.50 Regular Price £4.80 £4.00Vitcas-Fire Bricks-Yellow -

As low as £3.00 £2.50 Regular Price £4.80 £4.00VITCAS Fire Bricks-Brown

As low as £3.00 £2.50 Regular Price £4.80 £4.00VITCAS Fire Bricks-Brown -

As low as £3.00 £2.50 Regular Price £4.80 £4.00Vitcas-Fire Bricks-White

As low as £3.00 £2.50 Regular Price £4.80 £4.00Vitcas-Fire Bricks-White -

Special Price £3.00 £2.50 Regular Price £4.80 £4.00VITCAS Fire Bricks-Black

Special Price £3.00 £2.50 Regular Price £4.80 £4.00VITCAS Fire Bricks-Black