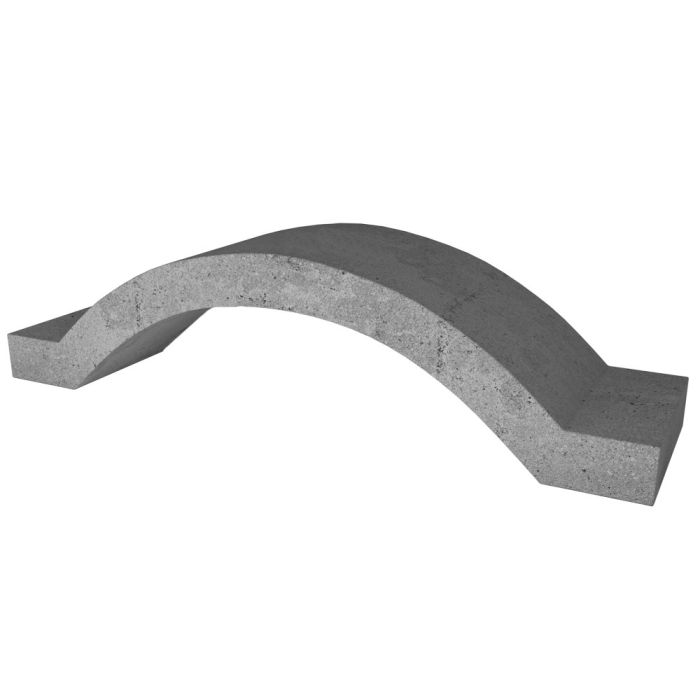

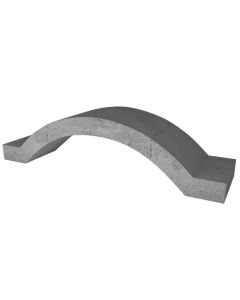

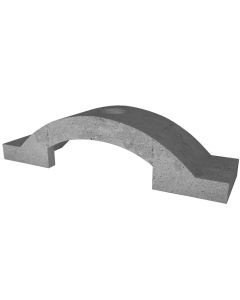

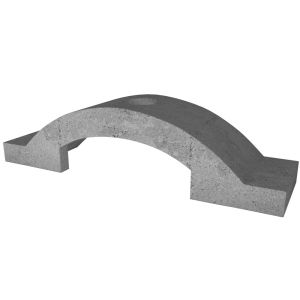

Outdoor Pizza Oven Arch

Benefits of Shopping with VITCAS

Direct from Manufacturer

Fast shipping – dispatch even within 24 hours

Guaranteed returns within 14 days

Dispatched from our UK warehouse – Worldwide Shipping

Secure payment via Visa, MasterCard, AmEx, PayPal & Stripe

Craft your own unique wood-fired bread or pizza oven with our premium Wood Fired Oven Heat Resistant Concrete Arch. This integral oven cast section, designed to form a tunnel-shaped oven, is meticulously manufactured from top-grade, high-temperature resistant materials. Its robustness and exceptional performance make it an indispensable addition to your oven construction.

The arch has been designed to integrate seamlessly with Vitcas 64mm fire bricks, and its 250mm radius offers ample and efficient baking space. The heat-resistant nature of this product, coupled with its high-quality construction, ensures that it can withstand the intense temperatures typically associated with wood-fired ovens.

Below is an example of how you can build a pizza oven using the Pizza Oven Arch.

To assemble a pizza oven approximately 1 metre in depth, you will require:

- 4 x Vitcas Oven Arch

- 1 x Vitcas Door Arch Section

- 1 x Vitcas Cast Iron Door

- 1 x Heat Resistant Silicone

- Flue Chimney with Damper

- 200 x Fire Bricks (230 x 114 x 64mm)

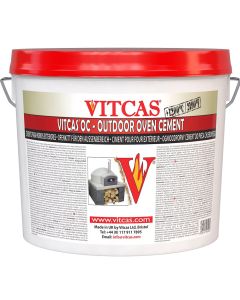

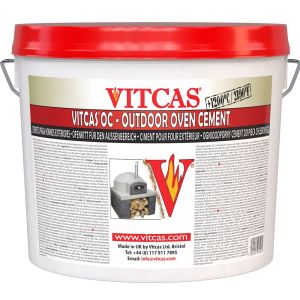

- 4 x 20kg Outdoor Oven Cement

The necessary insulation includes:

- 1 x Ceramic Fibre Board (50mm)

- 1 x Ceramic Blanket (7 metres)

- 1 x Oven Wire Mesh

- 1 x Ceramic Fibre Adhesive (310ml)

Instructions

- Construct the stand using bricks, leaving a central gap for wood storage. Fire bricks are suitable for this purpose.

- Support the concrete base or plinth with a metal bar underneath.

- Lay the 50mm Ceramic Fibre Board on the base.

- Cover the board with aluminium foil to protect the top surface.

- Start building the oven base with fire bricks, laying them out to form the oven's foundation.

- Apply Outdoor Oven Cement between each brick for a solid and secure foundation. Also, cover the edges with the same oven cement.

- After setting the base, build walls for the arches using fire bricks, roughly three layers of flat fire bricks should be sufficient.

- Arrange your Vitcas Oven Arch sections to form the tunnel shape.

- Place the 4 arch sections atop the walls and complete the back wall using fire bricks.

- Position the front arch door section.

- Install the door and surround it with fire bricks.

- Secure the arch sections in place using the Heat Resistant Silicone.

- Fit the Vitcas Door Arch Section and the Vitcas Cast Iron Door at the oven's entrance.

Now it's time to insulate.

- Attach the Ceramic Fibre Blanket to the oven's exterior using the Ceramic Fibre Adhesive.

- Wrap the oven further in the Ceramic Blanket and secure it with the Pizza Oven Wire Mesh.

- Apply Outdoor Oven Cement to protect against adverse weather conditions.

- Install the Flue Chimney with Damper atop the oven to ensure proper smoke ventilation.

- Allow the oven to dry and set according to the curing times provided with your adhesive and cement.

- Cure the oven using a small fire. To learn more, here is our blog on Curing a Pizza Oven.

- Once the oven is fully cured, you can paint it.

Now you are ready to cook delicious food!

| Product Group | Wood Fired Ovens |

|---|---|

| Outdoor | Yes |

| Manufacturer | Vitcas |

| HS Tariff Code | 6810990000 |

-

As low as £66.00 £55.00 Regular Price £95.99 £79.99Ceramic Fibre Board 1260°C-VITCAS Insulating Board

As low as £66.00 £55.00 Regular Price £95.99 £79.99Ceramic Fibre Board 1260°C-VITCAS Insulating Board -

Special Price £167.99 £139.99 Regular Price £240.00 £200.00Vitcas Wood Fired Oven-Plinth 1000mm

Special Price £167.99 £139.99 Regular Price £240.00 £200.00Vitcas Wood Fired Oven-Plinth 1000mm -

Special Price £180.00 £150.00 Regular Price £358.80 £299.00Cast Iron Oven Glass Door with Thermometer

Special Price £180.00 £150.00 Regular Price £358.80 £299.00Cast Iron Oven Glass Door with Thermometer -

Special Price £11.99 £9.99 Regular Price £23.99 £19.99CFA - Ceramic Fibre Adhesive

Special Price £11.99 £9.99 Regular Price £23.99 £19.99CFA - Ceramic Fibre Adhesive -

Special Price £17.99 £14.99 Regular Price £29.99 £24.99Pizza Oven Wire Mesh

Special Price £17.99 £14.99 Regular Price £29.99 £24.99Pizza Oven Wire Mesh